Exploring Manufacturing Overhead Costs and Calculation

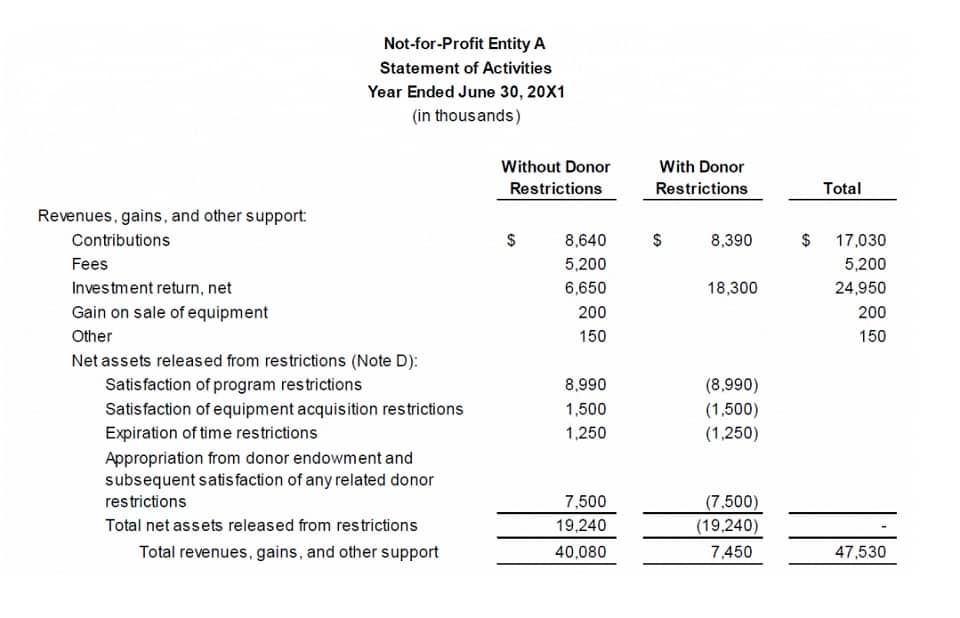

Typically, the manufacturing overhead is applied to the final product based on a manufacturing overhead absorption rate. For bookkeeping example, if you have $1,000,000 in sales and $150,000 in manufacturing overhead, your manufacturing overhead rate will be 15%. Manufacturing quoting and estimating software helps determine the cost of a project’s materials. A low percentage suggests the production process is efficient, While a higher percentage could indicate a lagging or inefficient production process. A common size production sheet is available from the ABC motors inc annual report.

Discover the Power of Inventory Source: An Introduction Video

After adding together all of the indirect expenses necessary to produce your product, this formula will give you the total dollar amount of manufacturing overhead. Learning how to calculate manufacturing overhead can help you employ better inventory management techniques and Bookkeeping for Chiropractors protect your business from going over budget. Manufacturing overhead also refers to the factory overheads or Manufacturing support costs.

- Calculating manufacturing overhead is only one aspect of running an efficient and profitable project.

- It’s added to the cost of the final product, along with direct material and direct labor costs.

- Let us understand the fixed manufacturing overhead formula that shall act as a basis for all calculations relating to this factor.

- UK accounting standards, like those set by the Financial Reporting Council (FRC), require businesses to reflect these costs accurately.

- You should estimate your costs for each of the manufacturing overhead costs that you identified.

How to Calculate Total Manufacturing Cost in Practice

Examples include metals, plastics, electronic components, and any other materials that are integral to the final product’s composition. Manufacturing costs constitute the entirety of expenses incurred during the production of goods. For any manufacturing operation, these costs are pivotal in determining profitability and competitiveness in the market. Understanding the components of manufacturing costs provides a clear picture of where expenses arise and how they impact the overall financial health of the business. We help small businesses increase their efficiency with user-friendly inventory management software. From running health checks on your inventory and accounting systems to sharing relevant formulas to crunch the numbers, we’ve got your efficiency needs covered.

- Manufacturing overhead costs are considered indirect costs because it is not easy to link them directly to a specific product produced.

- This method allows organizations to better allocate their overhead costs and determine which processes or products are most impacted by them.

- If it plans to produce 15,000 units the next year, the total manufacturing overhead can be predicted by multiplying the manufacturing overhead of one unit by the total number of units it intends to produce.

- Need help identifying the actual cost of your indirect expenses from product manufacturing?

- Whichever you choose, apply the same formula consistently each quarter to avoid misleading financial statements in the future.

- You should add these costs to the stock valuation of finished goods and work in progress.

- Additive Manufacturing (AM), often referred to as 3D printing, is a transformative approach to industrial production that enables the creation of lighter, stronger parts and systems.

How to Calculate Total Manufacturing Cost

To calculate total manufacturing costs, you need to add up three key components – direct materials, direct labor, and overhead costs. First, identify the cost of direct materials, which includes all raw materials used in production. Next, calculate direct labor costs, which are the wages paid to workers directly involved in manufacturing. Finally, allocate overhead, which includes expenses like utilities, equipment maintenance, and factory rent.

- These are employees who physically assemble the product or operate machinery.

- By following the steps outlined here, engineers across industries can achieve more streamlined and profitable operations.

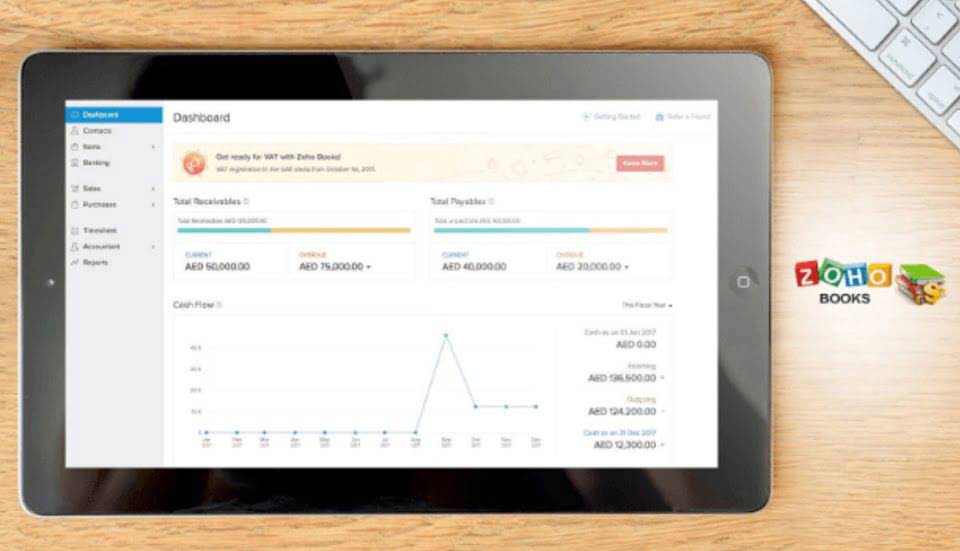

- ProjectManager has the tools you need to keep monitor and control all your costs, including your manufacturing overhead.

- For manufacturers, these costs are generally bought in bulk and added to overhead expenses since they support overall production rather than specific product lines.

- Indirect material costs are mostly related to consumables like machine lubricants, light bulbs , and janitorial supplies.

- Indirect costs include expenses like utilities, rent, maintenance, and indirect labor.

How to calculate manufacturing overhead?

- Companies discover these indirect labor costs by identifying and assigning costs to overhead activities and assigning those costs to the product.

- To calculate total manufacturing costs, use the total manufacturing cost formula.

- You also need to closely monitor your production schedule so you can make adjustments as needed.

- These are mostly fixed in nature and occur along with the start of the production unit.

- Additionally, revisiting service contracts for equipment maintenance and utilities can uncover opportunities for cost savings.

- This concept encompasses a wide array of technologies, from robotics and automation to artificial intelligence and nanotechnology.

After choosing an allocation method, divide the total overhead costs across your products based on machine hours or total manufacturing cost formula labor hours. For example, if your factory’s overhead costs are $10,000 and your machines run for 1,000 hours, you would allocate $10 in overhead per machine hour. This allocation ensures that overhead is fairly distributed among products, giving you a more accurate picture of total manufacturing costs. Manufacturing overhead costs are indirect costs related to the production of processes, while total manufacturing costs encompass both direct and indirect expenses. Total manufacturing cost will give you a clear picture of your overall manufacturing costs, while manufacturing overhead can help you accurately determine the indirect costs of your manufacturing process.

When you do this calculation and find that the manufacturing overhead rate is low, that means you’re running your business efficiently. The higher the percentage, the more likely you’re dealing with a lagging production process. The ability to track those costs is important and project management software can help. ProjectManager is online work and project management software that delivers real-time data to monitor costs as they happen. While we have many project views, the Gantt chart contains key details on how much you’re spending on production.